What is open-loop tension control?

What is closed-loop tension control?

Open-loop control is sometimes called non-feedback control. Open-loop control may be as simple as setting an input variable to a fixed value, such as setting a brake at one condition, or it may be fairly intelligent, such as varying a rewind clutch based on calculated roll diameter and weight. However, in either case, open-loop control avoids the thing that seems most obvious, it never measures the variable you are trying to control, in this case, web tension.

When you drive your car, you have the choice to control your speed with either open or closed-loop control. When you manually control the gas flow with your foot on the accelerator pedal, you are running in open-loop control. The accelerator and gas flow changes the engine’s torque output, not speed. Torque applied to the car’s mass creates acceleration. You have a device measuring your car’s speed, the speedometer, but you have to close the loop through your eyes, brain, and reflexes to determine when the gas flow results in the acceleration and speed you desire.

Alternately, using the car’s cruise control is a closed-loop system. Your eyes, brain, and reflexes are replaced by a controller. You set what target speed you would like and the control loop automatically adjusts the gas flow so the car runs at that approximate speed. The car should average the target speed and vary slightly above and below that target speed as the control loop does its job. These small errors are required for a closed-loop system to work, as the controller is waiting for deviations from the setpoint to trigger the need to adjust the input or dependent variable (in this case gas flow). The gas flow will vary depending on speed setpoint, accelerations, gravitational forces of going up or downhill, rolling resistance, wind resistance, and more.

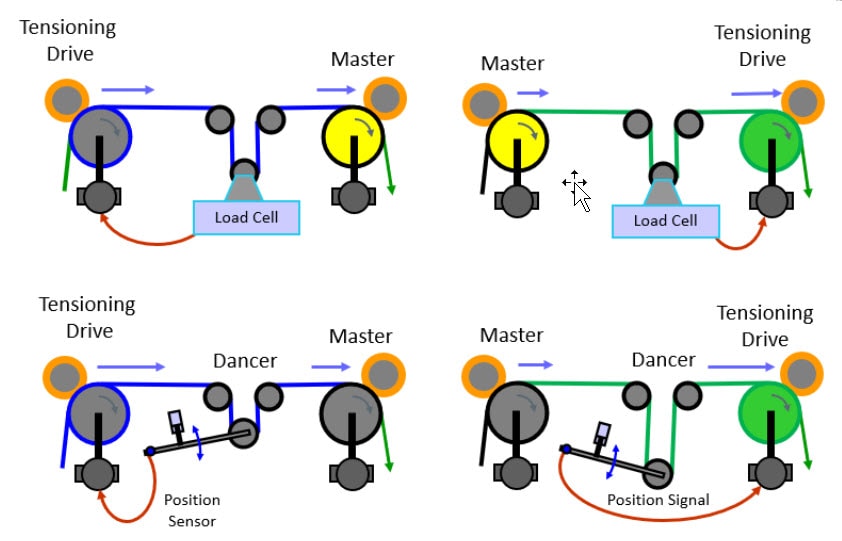

Closed-loop control, or feedback control, measures or reacts to changes in the variable you are hoping to control – tension. Direct tension measurement requires a force transducer or load cell to measure the force between the web and the equipment framework, usually through a roller mounted on two load cells. Alternately, instead of measuring the web force, a dancer roller attempts to exert a controlled force into the web and the closed-loop tension control works to maintain control of the web within the accumulation range of the dancer roller’s stroke.

When is open-loop tension control used?

Though in most cases I will advocate closed-loop tension control as your best choice, I can see a few reasons for the use of open-loop tension control.

-

Open-loop systems are simple and usually less expensive than a closed-loop system.

-

In some cases, it may be difficult or impossible to measure tension, so without feedback, by default, you must choose open-loop control.

-

Your process or product is sensitive to or dependent on consistent control of speed, length, or a timed event.

-

You need to speed match equipment to the web where there is limited or no traction.

When is closed-loop tension control used?

Closed-loop control, most commonly PID control, is the best way to ensure tension is at the value you desire and will react to tension upsets in a expedient manner. Closed-loop tension control most commonly uses a dancer roller or load cell roller to sense changes in web tension and provide a signal to compare to a set point. If the measured value varies from the desired setpoint, the closed-loop system will adjust the controlled variable, usually speed or torque, to move the tension back towards the desired value.

A closed-loop tension control usually goes beyond simply measuring tension and adjusting the speed or torque with PID values tuned to the web properties and equipment characteristics; closed-loop tension control will usually include feed-forward to proactively adjust torque or speed to follow known speed changes (such as acceleration and deceleration) and inertia changes (such as changes in winding or unwinding roll diameter, roll material density, or roll width).